- Why is it vital to monitor loads at LIVE EVENTS when heavy light, sound and video equipment is hanging above the audience?

In our modern era, live events are characterized by ever more complex arrays of dynamic light, audio and video equipment, often resulting in tens of tons of massive equipment being suspended directly over people’s heads – creating a huge safety challenge.

- If I know the weight of each speaker, light and video wall, is that data not sufficient to prevent overload?

Unfortunately not. The problem lies not just in the total weight of the suspended load but in the load distribution: Each time there are more than two hoists on a truss or more than three hoists in a structure, it becomes statically indeterminate, resulting in unpredictable load distribution. In most cases this will cause a load imbalance, in which some of the hoists may reach overload while others carry only a small part of the load. This is a highly undesirable situation that can result in dangerous overload.

- How can I immediately identify an overload as it starts to develop?

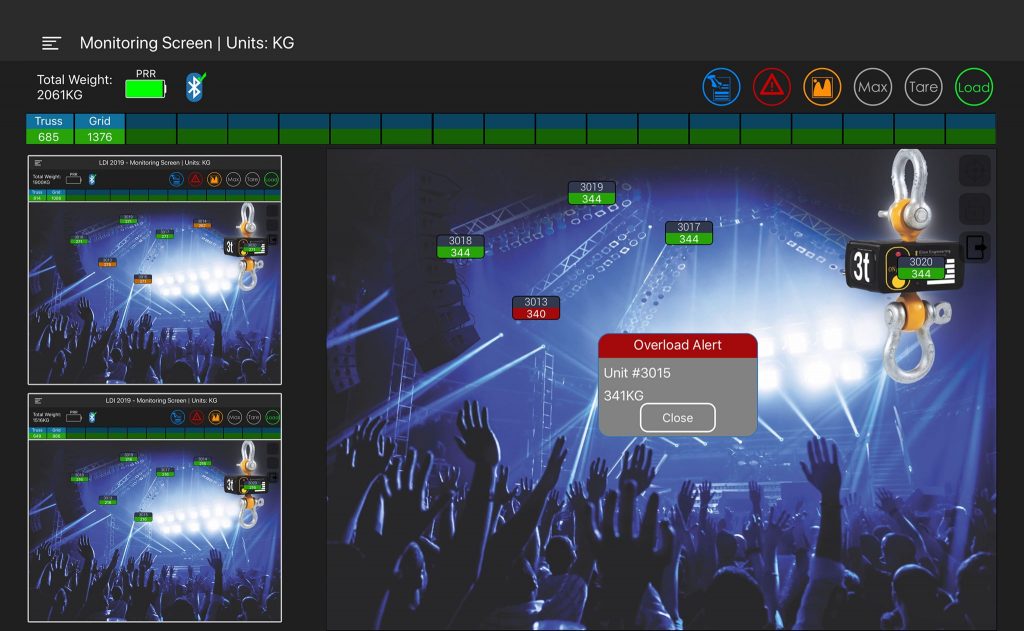

For simple integration with the rigging plan, the software enables overlay of the load map right onto the rigging plan on screen, making it easy to see where motors and loads are situated. Or – you can even just take a snapshot with your iPhone of the venue structure, and use the resulting pic as the rigging plan. The fact that the load cells on the load monitoring map reflect their real position, enables the rigger to immediately identify the location of a potential overload and take swift preventative action. The set point option has an overload/ under-load alarm (visual and audible) that automatically instigates immediate motor stop in the event of an overload.

- How many load cells are required in order to ensure safe suspension of equipment above the audience?

The more hanging points with a load cell installed – the safer the entire installation. But you can still start off small and expand over time. We have starter kits with just 4 load cells, mini-kits with 8, midi-kits with 12 and the ideal for maximum safety is to install a load cell on each and every hanging point.

- Why is it important to continuously monitor the loads?

Continuous load monitoring from the moment of installation, continuing throughout the entire duration of the show and until tear down is of crucial importance to prevent overloads. Sleep or stand-by modes are not acceptable from a safety perspective. Even when the power is shut off after setup is complete, it is essential to continue monitoring the loads, as overloads can occur at any time due to unpredictable occurrences such as lifting or suspending device that fails thus causing a different load distribution, or the addition of more equipment that someone decides to hang at a later stage.

- When the power is shut off after setup, how can I continue to monitor the loads?

Ron StageMaster’s unique, extremely long battery life of 5000 hours provides continuous load monitoring which is paramount for optimal safety.

- What are Ron StageMaster’s main advantages?

- Bluetooth compatibility with iPhones / iPads (no Wi-Fi required)

- Average response time less than 1 second for up to 200 load cells

- 0.1 percent accuracy with Eilon Classic load cells

- 24/7/365 continuous load monitoring

- Unbeatable standard battery life up to 5,000 hours

- Extreme range up to several km/miles

- 200 load cells per monitoring station

- Proven wireless technology since 1976

- Fatigue-rated load cells

- Why are Eilon Classic load cells superior to shackle pin load cells?

Unlike the Eilon Classic load cells, the shape of shackle pin load cells does not deliver high accuracy, linearity and repetitiveness.

- How fast do the measurements update on the real time load map?

Ron StageMaster has an extremely short response time by monitoring up to 200 load cells per second.

- How can I retroactively track the load monitoring of a specific event that took place several weeks or even months ago?

Ron StageMaster provides a record at the end of each event that contains data reports collated over the last few months, and even sends SMS alerts. Reports include loads of all load cells at a rate of one per second.

- How accurate are Eilon Classic load cells?

The Eilon Classic accuracy rate is +0.1% of full scale.

- How long will the batteries last before I need to replace them?

Unique battery life provides up to 5,000 hours of continuous monitoring. You can see the battery life status on-screen at any time and a low battery alert appears when approximately 30-50 hours of full battery strength remain.

- Is overload of up to 10% allowed?

No, any overload is strictly forbidden.

- Over which technology do the wireless load cells transmit?

The Ron StageMaster load cells transmit over radio Frequency (RF) technology.

- Will other wireless transmissions or the many steel structures that are common in live events affect the wireless signal of Ron StageMaster?

Our wireless technology successfully overcomes all these challenging environmental conditions and Ron StageMaster continuously provides a strong and reliable signal. Decades of intensive experience with projects for the aerospace industry (especially in launching sites – e.g. NASA), has enriched our know-how and expertise – all of which has been implemented in the Ron StageMaster systems.

- Can I see the real time load monitoring map on my smartphone?

Absolutely! That’s what it’s all about .. you can see the load map on your laptop screen with our CRR (Central Radio Receiver), and/or directly on your smartphone or tablet screen using the PRR (Portable Radio Receiver).

- What is the maximum number of Ron StageMaster load cells that can be monitored?

The PRR (Portable Radio Receiver) displays measurement data for up to 40 load cells. The premium CRR (Central Radio Receiver) displays measurement data for up to 200 load cells. You can use as many CRRs as you need in accordance with the total size of each specific event – making the maximum number of monitored load cells practically unlimited. You can combine the use of CRRs (for maximum monitoring capacity) and PRRs (for ease and comfort of use for riggers) on the same site.

- What is the transmission range of Eilon Classic load cells?

The range is up to 150 yards / meters (line of sight, outdoor). Optional extended ranges are available for up to several kilometres/ miles.

- Is it possible to monitor the loads in several halls from one control room?

Yes, it is possible, using the Ron StageMaster Slave / Master / option as well as data export by Ethernet.

- How can I receive an overload warning even if I am not on site?

Ron StageMaster offers an SMS text alert option which enables sending text message to pre-defined phone numbers in the occurrence of any overload.

- What standard of service can I expect?

We have service centres worldwide providing real time support: we are available almost 24/7 by either phone, email or chat.

- What is the relationship between Eilon Engineering, Ron StageMaster and Ron Crane Scales?

Eilon Engineering, established 40 years ago, is the company who designs, manufactures and markets all our products. Ron StageMasterTM is the brand name of our innovative, wireless load monitoring & overload prevention system for live events, that for 10 years has been successfully protecting conventions, trade show & cultural centers, arenas, opera houses and world famous TV and theatrical productions spanning the entire globe including Cirque du Soleil, Metallica, MTV Video Music Awards, Elton John, Mamma Mia ,The Blue Man group, and many others. Ron Crane ScalesTM is our brand name for the industrial market for valued customers like NASA, Boeing, GE, Siemens, Lockheed Martin and many, many more.

- Are there copies of the Eilon Classic on the market?

Unfortunately, as with any successful and leading product in the market, our Eilon Classic load cells have fallen prey to this syndrome, and an inferior copy is being marketed by a different company under a different brand name. So do beware! And for ultimate safety and protection, make sure what you are purchasing is a Ron StageMasterTM system manufactured by Eilon Engineering.

- When is it recommended to use wireless load cells vs. wired load cells?

Eilon Engineering manufactures both. In permanent installations it is usually recommended to use wired systems, while the wireless, “Plug and Play” system is usually the preference in all other instances, since installation is fast and easy, and eliminates messy cabling and lengthy setup time.

- Which capacities and safety factors are available?

Eilon Classic load cells are available in any capacity up to 300t, in either 5:1 or 10:1 safety factor.

- Is it possible to pre-set different overload limits for different load cell groups?

Yes, of course. You can pre-set up to 15 different groups, each with its own overload and underload limits. Each load cell can be part of several groups and at the same time have its own overload and underload limitation as an individual load cell.

- What are the Ron StageMaster systems composed of?

The system is composed of load cells (you can combine different capacities and safety factors), carrying cases (or flight cases) and receiver/s – desk (CRR), portable (PRR), 19″ rack or a combination of all of these.

- What are the Eilon Engineering load cells made of?

All Eilon Engineering load cells are made of high quality, aerospace steel.

- Are all Eilon Engineering load cells fatigue rated and what does that mean?

Yes, all Eilon Engineering load cells are fatigue rated, which means that the load cell is not limited to the number of loadings during its entire life time (as long as the safe working load is not exceeded). Fatigue rated classification is proof tested at 20,000 loading cycles of 150% loading. This is of prime importance for maximum safety.