As events increasingly feature heavier rigging setups—particularly large LED screens—Cape Town-based Core Productions has taken a proactive step to enhance safety by investing in a CHAINMASTER CELLMASTER load cell monitoring solution, supplied by DWR Distribution.

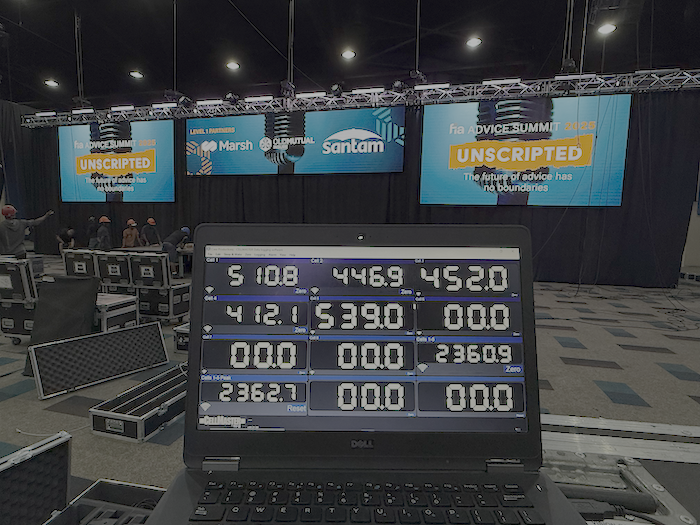

The new load monitoring system was immediately put to use mainly focused on rigging LED screens due to the weight implications that gets spread across points. For company owner, Bernard Gramann, the investment provided both technical control and much-needed peace of mind. CELLMASTER, the wireless load cell monitoring solution from CHAINMASTER, delivers precise monitoring and logging for rigging installations. Core Production’s new gear comprises 8 Load Cell Shackles (3.25t), one CELLMASTER and USB Base Station, all housed in a carry case.

“It’s a game-changer to eliminate the guesswork from load distribution,” says Bernard. “When flying heavy LED screens, even the smallest adjustment—like a single click on a monitor—can drastically shift the load, sometimes increasing it fivefold on a single point. That kind of variance can compromise rigging safety if not properly managed.”

At a recent event hosted at Sun City, for example, the venue’s rigging points were rated at 250kg each, offering limited tolerance. The rig comprised eight points—three on the left, two at the centre, and three on the right. Given the close margin, Bernard approached the job with caution.

“Flying LED screens safely means knowing exactly what each point is bearing. Using load cells gave us real-time visibility,” he explains. “With a 3-point pick-up, the centre point can carry as much as 62% of the load. Thanks to the load monitoring system, we were able to make real-time motor adjustments and redistribute the load evenly. It worked flawlessly.”

The Core Productions rigging team was equally impressed. Being able to detect if one motor was running faster than another allowed them to correct imbalances before they became a safety concern.

“Our lighting rigs rarely pose a problem—they’re lighter and the weight is more evenly distributed,” Bernard continues. “But LED screens are another story. As they grow in size, they become significantly heavier, and the risks increase. Globally, we’ve seen more LED screen collapses than failures of lighting or audio rigs. That’s why I strongly believe any team flying LED screens should be using load cells—for the safety of their crew, equipment, and the audience.”

Bernard also expressed his appreciation for the support he received from Robert Izzett at DWR Distribution. “Rob was incredible—he educated me on the load cells, helped me get started, and was available to assist, even on weekends while out cycling! He embodies what DWR is all about: supporting people. I’m grateful to the entire team.”