Urban Brew Studios was the home to The Voice South Africa. In time for the new season, studio ten – where The Voice was shot – as well as four other studios on the premises, received a massive upgrade ranging from walkways, trussing, hoists, curtain tracks and pulleys. DWR Distributions’ theatre manufacturing department were commissioned for the project by Protea Electronics.

“To me this project was all about the people, the achievement, the deadlines and challenges too,” explained Jacques Welthagen from Protea Electronics. “Protea Electronics was chosen as the preferred turnkey supplier to furnish the complete facility including grids, trussing and lighting displays. We in turn looked to our partners for their solutions and expertise.”

Rob Young and Keith Pugin from DWR designed and oversaw the install of the project. The services of Jacob Mogale of the Install Crew, was also utilized for additional hands on deck.

Timelines and critical on-air dates pushed the teams forward. “As the building had existing roof trussing and was not originally built for television, grids had to be custom built for each specific studio; there was no retrofitting of off the shelf lighting grids,” said Jacques. “The DWR team successfully designed and installed all of the grids; one motorised, one walkway based, two standard pipe grids and the other, a mother grid which were all approved by the structural engineer.” The configuration of the grids and infrastructure at Urban Brew lends itself perfectly for any kind of productions coming their way.

“The biggest challenge was to find the right solutions at the right time within the budget constraints,” said Jacques. “It included a seven-day week for a period of six months where each subcontractor had to pull out all stops to be able to supply within the allocated time.”

In actual fact, the studio was a building site and the experienced Urban Brew crew had to keep productions running and allocate which gear would be allocated where and when!

Studio One was first in line for the makeover. “We installed six trussing units, each consisting of a 6m x 6m square comprising of Prolyte trussing, mounted on a pulley system,” said Rob. “Each individual truss can be brought up and down on our locally manufactured pile wound hoist which is powered by a portable motor. The benefit of a portable motor means we only had to buy one to run six hoists.”

Both Studio three and six have fixed pipe grids in the roof. In each studio DWR installed a permanent 2m x 2m lattice of tubing which is fixed up in the roof space, close to the top onto which lighting fixtures can be hung.

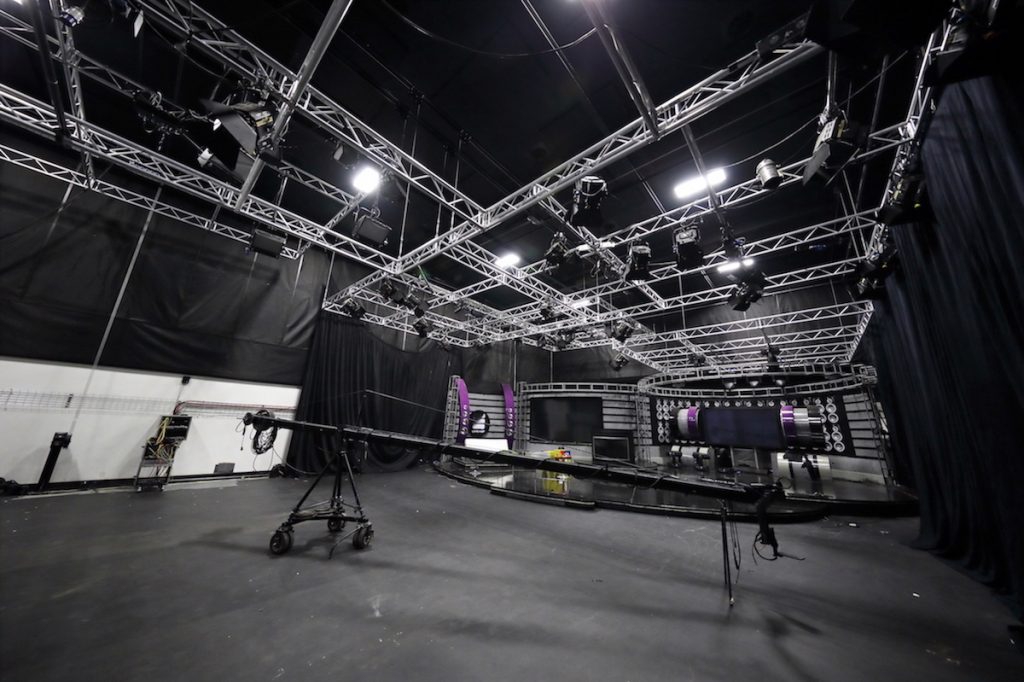

“For studio ten we were under whip to be ready in time for The Voice,” said Rob. The Voice production required extra height for filming purposes. To solve the problem, DWR installed 13 x 26.5m lengths of heavy duty Prolyte H40V trussing across the width of the studio, fixed right up against the girders and walls. In the case of The Voice, it was used as the mother grid.

Studio nine includes a new and prominent feature, designed by Rob, a 10m central walkway with seven side walkways leading off it. On either side of the walkways are pipes onto which lighting fixtures can be hung. The pipes are accessed on either side of the studio by a cat ladder. The new system allows the crew to walk above the studio, haul up lights and hang them.

A curtain track which surrounds all four sides of each studio, was installed in studio one, three, six, nine and ten.

“We could not have asked for a better partner in this case and were bowled over by the professionalism, speed and attention to detail in their designs and workmanship, not forgetting that they always smiled and kept the spirit high,” said Jacques. “It was always a positive sign to see the DWR crew arrive with their ear to ear smiles and getting the job done right first time. Apart from the grids, DWR also consulted and advised on a broader spectrum of services required, and again the expertise and knowledge factory was massive and mature. The team can be highly recommended and we hope to do many more of these kind of projects around the world should we get the opportunity.”

“It was a pleasure to work with such a professional team,” ended Rob. “Thank you to everyone at Protea Electronics for making this project possible.”