21 February 2008

Gearhouse Supplies 46664 Concert

Gearhouse South Africa supplied design, full technical production and crew to the amazing 46664 Concert staged in Johannesburg’s Ellis Park stadium on World Aids Day.

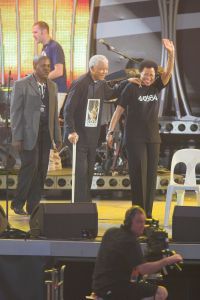

The landmark show featured an address by Nelson Mandela and a line up of leading local and international performers including Just Jinger, Freshly Ground, Johnny Clegg, Jamelia, Corrine Bailey Rae, Goo Goo Dolls, Razorlight, Live, Peter Gabriel and Annie Lennox. Live high-profile personal appearances also included Naomi Campbell.

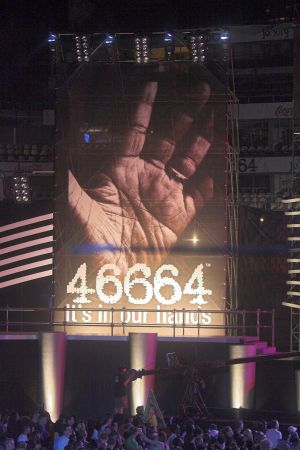

Imprinting the dramatic strap line “It’s In Our Hands” on people’s minds and aimed at raising AIDS awareness, 46664 Jo’burg was watched by 40,000 music fans in the stadium and broadcast live to millions of people around South Africa and the world by the South African Broadcasting Company (SABC).

Imprinting the dramatic strap line “It’s In Our Hands” on people’s minds and aimed at raising AIDS awareness, 46664 Jo’burg was watched by 40,000 music fans in the stadium and broadcast live to millions of people around South Africa and the world by the South African Broadcasting Company (SABC).

The striking stage set, lighting and visuality of the event was designed by Gearhouse Director, Tim Dunn.

He faced many challenges. A major one was ensuring that it looked equally as good on camera for the broadcast IMAG mix directed by the legendary Aubrey ‘Po’ Powell, as it did for the live audience. Another was building enough flexibility into the system to keep each act looking fresh and different, particularly for the after dark section, whilst also creating an eye-catching design that worked in daylight.

Dunn wanted it to be contemporary, distinctive in its own right and totally different from the inaugural concert in Cape Town in 2003 and the 2005 Concert in George. The gently curvaceous super-wide result presented a sense of spectacle and plenty of lasting positive visual memories for those involved with the show.

In addition to the main 25 metre wide stage, there were also stage left and right ramps and long offstage wings to either side, which offered further performance areas.

To ensure there was sufficient eye candy and depth for the cameras – particularly during the daylight section of the show, Dunn designed curved LED columns right at the heart of the 18 metre central stage revolve. The specially fabricated column framework, complemented by Optiscreen VP10 modules, was comprised of 5 columns on each side of the revolve – each measuring 4.80 metres high by 1.28 metre wide. Above these was a 12.20 metre wide by 1.52 metre deep strip of Lighthouse R16 LED, which was used for slogans and strap lines, and which also blended in with the general screen content.

Overhead, the main architectural elements of the lighting rig were 6 upstage/downstage trusses curving downwards at the downstage edge. Robe ColorWash 2500 moving lights were rigged onto the curved ends and utilised for the high level key lighting of performers – their position giving them access to hit any part of the stage. Eighteen Atomic strobes were positioned on the back end of these trusses.

In between the 6 curved-end trusses were another 5 straight trusses rigged at a higher trim, all fully loaded with PARs and used for general stage wash coverage.

Dunn used a combination of over 200 moving lights – a heterogenic mix of Robe, Martin and High End fixtures – scattered all over the rig, including some on the floor and others illuminating the various set elements.

Sixty-two i-Pix Satellite LED ‘bricks’ were utilised to tone the set and trusses and the main onstage set pillars were illuminated with Martin Professional Mac 250 Wash’s and Highend Studio Colour 575’s.

Twenty-four 8-lite blinders were rigged around the(?) top perimeter of the set for audience illumination.

At FOH, Dunn worked closely with lighting director Hugh Turner – the two are a regular double act – running 3 GrandMA consoles. One was purely controlling show lighting, one was used to run a host of digital media created and stored in two Grand MA digital media servers and the third was for audience and additional TV lighting plus back-up.

They were controlling over 616 fixtures and desk channels with over 4500 parameters and 12 DMX universes.

Dunn is the first person to acknowledge that it was a big team effort to get the visuals spot on – which also included Chris Grandin and Marcel Wijnberger from Gearhouse Media who created additional custom video content for the show, including the 46664 logo and strap-line on the LED Screens.

(Left: Tim Dunn)

(Left: Tim Dunn)

Pete Currier was Gearhouse’s daytime project manager for lighting and set. He co-ordinated all the disciplines involved in the installation and set up, and ensured the correct interpretations took place between the creative elements of the design and the logistics required to make it happen. This involved him working with up to 170 different people each day as the build gathered pace and intensity. Candice Scott took over as the night time project manager.

(Left: Pete Currier)

(Left: Pete Currier)

Sound

Gearhouse Johannesburg’s Audio Operations Manager Dave Tudor, system designed and co-ordinated the supply of all-things-audio for 46664. As part of this, Gearhouse asked Britannia Row in the UK to send a team of 7 engineers and technicians to help run the FOH and Monitors. Britro has been involved in 46664 Concerts since the first one in Cape Town in November 2003.

They chose a well tried-and-tested Turbosound Flashlight system, flown 8-wide and 4-deep either side of stage, together with 74 Flashlight subs on the stage – 36 a side, plus a further array of 16 TSW124s a side for additional movement!

Although the system sounded awesomely loud, clear, rich and perfect for a stadium gig, the system was actually on it’s front line, with Gearhouse taking delivery of a new L-Acoustics V Dosc system just 2 weeks after this show.

For delays they used 12 L-Acoustics Kudos per side, hanging off TFL towers just behind the main FOH tower.

The FOH console system was supplied by Britannia Row, consisting of two Digico D5s, set up in classic festival A/B style, with a Midas XL3 “showboard” from Gearhouse to run the Soweto Gospel Choir, VT playback and all the presenters’ mics.

Processing was a combination of XTA 224s and 226s, all being routed via Dolby Lake Contours, and amplification was an amalgam of BSS760s and 780s, with the ground stacks powered by MC2 760s and 1250s and L-Acoustics LA48s for the delays.

There was some outboard processing available at FOH – in the form of TC system 6000 digital reverb, Avalon tube compressors, along with TC 2290 delays and a Lexicon PCM 91, all of which were made available for general use.

The Brit Row team was led by crew boss Andrew Burch who worked alongside Gearhouse’s system tech Jaco De Wit in dealing with several visiting sound engineers as all the major acts and a proliferation of the local acts all brought their own.

The audio stage team was headed by Britrow’s Stefan Krista, who also handled the daunting task of collating the specs of all of the bands to create the show patch.

Monitor world was kept in check by Gearhouse’s Revil Baselga and main engineer Andreas Furtner, plus 4 stage techs doing mics and lines.

The monitor consoles were two of Gearhouse’s new Yamaha PM5Ds, being run through a Yamaha DME 64 router for re-patching.

Gearhouse provided 40 L-Acoustics HiQ 115XT wedges for the stage, and the side fills were 3 L-Acoustics Kudos a side, stacked vertically as opposed to horizontally, with SB 118s for the bottom end.

Gearhouse started discussions with Britannia Row a month ago about their role in the sound equation. There is a long history of co-operation between the two companies, and Tudor explains that it was also a great experiential opportunity for some of his less experienced crew members to work with the Brit Row engineers. Both teams integrated perfectly and enjoyed the experience.

Sennheiser supplied the whole microphone package which was looked after by Dave Hawker and Mark Saunders from the UK working with Sennheiser South Africa for any additional requirements.

Sennheiser has been involved in sponsoring equipment for all the 46664 concerts and also has a close relationship with Britannia Row.

The Sennheiser 3000 system they used consisted of over 80 channels of wireless plus SKM5200 hand-held mics with Neumann heads, Sennheiser EW935 vocal mics and EW300 IEM systems. Then there were approximately 250 additional Sennheiser and Neumann wired mics.

The Sennheiser 3000 system they used consisted of over 80 channels of wireless plus SKM5200 hand-held mics with Neumann heads, Sennheiser EW935 vocal mics and EW300 IEM systems. Then there were approximately 250 additional Sennheiser and Neumann wired mics.

The kit and infrastructure included a huge antenna array to make it work across the whole stage area, together with some “magic” touches to make it “really fly”.

Working closely with Gearhouse once again was an experience they’ve found “Absolutely excellent.”

Screens & LED

Gearhouse sister company LEDVision supplied all the LED screens, overseen by LED Director, Richard Baker. He was stationed in one of 3 OB trucks for the show mixing the screens via Gearhouse’s new Vista Spyder in 1920 x 1080 pixel HD.

He had feeds from 8 of SABC’s cameras, along with off-site pre-edited material from the production companies, stored on two EVS machines, and custom content made by 46664’s production company on another EVS. There were also the two feeds from the GrandMA digital media servers being run by lighting.

Part of Baker’s role was to keep continuity between lighting and screens onstage. Developing the harmony between lighting and screens/video is characteristic of the way Gearhouse is currently working – mixing the two mediums to offer a new dynamic aspect to their show visuals.

All those inputs went to three sub-mixes in the van which in turn was routed to Gearhouse’s Vista Spyder controller for outputting to screen. Additionally, there was a live website feed tracking all the public text messaging which was filtered and then sent to the Spyder. Baker could therefore have control of the overall graphics backgrounds, so when Po went to a wideshot of everything onstage, he could switch to one coherent look across all the screen surfaces.

Baker also had Po’s IMAG mix (being cut in another OB truck) coming to him in the OB truck, and this was output to the two side stage 7.11 by 3.81 metre IMAG screens below the main PA hang, made up of Lighthouse R16 modules. In addition to the stage and side screens LEDVision provided two 5.08 x 3.05 metre Lighthouse R16 delay screens positioned off the FOH tower for the benefit of the crowd further back.

Baker worked with local Operations Manager, Allen Evans and UK-Based LED Screen technician Pete Ewans alongside 11 other LEDVision crew. Their challenge was in deployment of LED equipment over the various LED–intensive events during the same period across the country, including the FIFA Preliminary draw that took place a week earlier in Durban.

The complexity of the set design – built by another Gearhouse company, In2 Structures – and integrating the various video elements with this – was also a challenge.

Power

Gearhouse Power’s Anthony Sackstein was responsible for installing enough generated electricity at Ellis Park to handle all the technical production’s requirements for the show, which was divided into 4 different areas and supplies.

The first was a 1200 Amp 3-phase supply (4 x 300 KVAs) for generic lighting; the second was the stage right automation supply (2 x 300 KVAs) which dealt with all the moving lights on that side of stage plus anything with a ballast or running DMX, and this was mirrored by a similar supply on stage left. The fourth supply consisted of two 250 KVA sets for Audio, AV and LED screens. Each of these 4 supplies was synchronised to a back up generator as an additional precaution.

Eighteen runs of approximately 100 metres of mains cable were run all around the venue, including 2 at 150 metres and one at 200 metres.

Gearhouse Power had four techs on site including a wireman, 2 electricians and one power technician.

It was one of the first outings where 5 of Gearhouse Power’s newest fully synchronisable, trailer-mounted Caterpillar generators were utilised. All Gearhouse Power machines are built and designed specifically for show purposes and for 46664, 5 additional machines were subhired from approved suppliers.

Rigging

Gearhouse Rigging’s domain was overseen by Operations Manager Anthony Banks and head rigger Graham Brooking worked with a team of 6 on site riggers.

They had 84 points of rigging in total between lighting, screens and PA, and used a selection of 1 and 2 tonne CM Lodestar hoists.

The Stageco roof was loaded almost to capacity with 19 tonnes of lighting and screen in the main roof, most of it towards the front so that weight distribution along the roof trusses was a major challenge for rigging.

Staging

Staging

Chris Loeijs co-ordinated the stage erection, based on a standard Stageco configuration with some special elements. He worked with 4 senior crew, 4 juniors and about 20 locals.

Measuring 70 metres side to side, with 1200 square metres of decking and 250 tonnes of steel, the wings were a little higher than standard to carry the extra load, and it was five towers wide rather than the normal four to accommodate an additional 5 tonnes of lighting and screens on the main span.

The 12.9 metres headroom offered plenty of scope for the lighting and stage set to look its fabulous best, with the whole construction standing at around 18 metres in height.

The construction also included an impressive 120 square metres a side of backstage and offstage storage facilities, plus another 100 square metres at the back.

Two ramps were built for backstage access, a steeper one on stage right for the load in and a gentler version on stage left for the get out. They also installed over 300 metres of crowd barrier and 120 square metres of rolling risers.

The revolve was built by Lee Irving from Gearhouse In2Structures, a specialist set and structures building company. Measuring 18.3 metres in diameter and weighing 13 tonnes, it turned on two 5.5 Kw motors, optimised to perform the manoeuvre in a relaxed 68 seconds, although it could rotate the 180 degrees in as little as 10.

In2Structures also manufactured and built various set pieces including the metal ‘trees’, the Optiscreen column cages and the huge printed scrims on the set and below the LED Screens either side of the stage. Joburg Set Company built the scenic columns along the front of the stage and the decking around the revolve.

Production.

Gearhouse’s Ofer Lapid asked UK-based production manager Nick Levitt to take on the role of production director for the event. He worked with production managers Kenny Underwood (UK) and Micky Lehr (South Africa) and stage manager Nick Rea. Levitt has done lots of work with Gearhouse over the years and was also involved in the first 46664 in Cape Town, as well as having a vast experience of multi-act events.

He brought in his technical manager (Nick Evans), engineer and CAD drawer to help oversee the engineering aspects of the build and the health & safety.

Locally based Micky Lehr dealt with most of the site management and issues including dressing rooms, portacabins, site layout, accreditation, liaison with the stadium and the local authorities, police, etc.

Levitt came on site two weeks beforehand. “It’s totally different to working in Europe or the US, and the pace and the resources are not the same, but it’s gone extremely smoothly, and it’s been great to work with Gearhouse” he comments, adding that it’s definitely been an advantage to be dealing with just the one company for all aspects of the technical production.

Levitt came on site two weeks beforehand. “It’s totally different to working in Europe or the US, and the pace and the resources are not the same, but it’s gone extremely smoothly, and it’s been great to work with Gearhouse” he comments, adding that it’s definitely been an advantage to be dealing with just the one company for all aspects of the technical production.

Micky Lehr describes working at the Ellis Park site as similar to “Doing F1 in Monaco”, with real estate at a complete premium and everyone wanting a piece of the action! He was also the link between everything happening onstage and local promoters Real Concerts.

One of the complications was that Ellis Park is still under construction as part of a major refurbishment, so in addition to his own staff of 100 plus, Lehr had to contend with hundreds of construction workers and their plant all over the place throughout the build process! It was also 6 years since the last gig there, and they only officially moved into site 2 weeks before the show – which was a very short lead time in which to produce a world class event.

Security was exceptionally tight – considering the VIP list – but they had great support from the City of Johannesburg, which paid for staging the event, and also from the Metro Police Services and the South African Police Services.

On the day, they took the opportunity of a large event in the downtown location to implement some of the procedures being put in place for the 2010 World Cup in terms of crowd control, site egress, etc.

46664 Johannesburg proved beyond a shadow of doubt that South Africa has the creative and technical production talent to stage world class events. The show also saw Gearhouse step up to the challenges of making a globally significant multi-media event a real success by investing in the right people, spirit and attitude …. Along with the appropriate equipment.